Piston Pumps

A recognized leader in piston pump technology

Municipal Products & Industrial Products

Originally designed to pump concrete, the Schwing Bioset piston pumps adapt easily to the rigors of wastewater treatment plant service with a proven history of reliability and ease of maintenance. Many units have operated continuously for years with 99% availability. Schwing units pump dewatered biosolids from Belt Presses, Centrifuges, Plate and Frame Presses, and Rotary Presses with dry solids content up to 56%. The pumps have volumetric capacities over 310 GPM and operating pressures up to 1,885 psi.

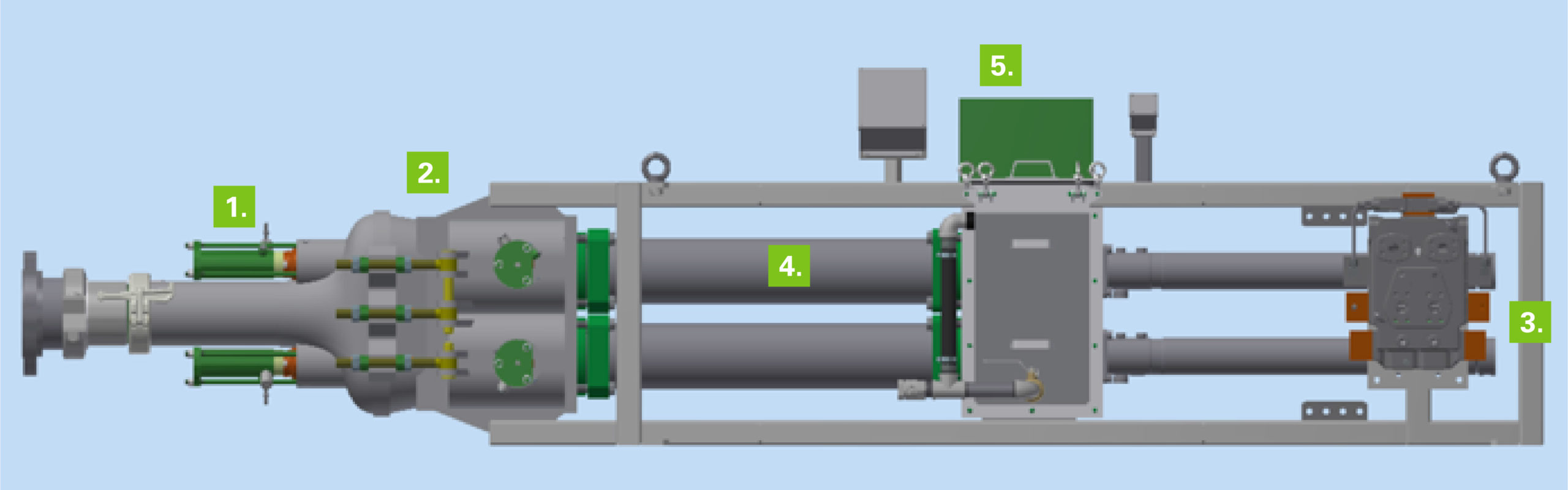

PUMP

2. Poppet Valves – Streamlined design that has remained unchanged for over 30 years. Poppet valves are ideal for sludges, slurries, and pastes and prevent material backflow into the pump.

3. All Hydraulic Switching – Piston pumps are installed in some of the harshest environments on the planet. All hydraulic shifting means you don’t have to rely on the performance of electronics to pump operation.

4. Vertical and Horizontal plane pump – configurations ensure the ideal pump arrangement can be provided for your system.

5. Two-Handed maintenance controls – provide ease of servicing the pump with local controls, yet ensure staff safety by requiring hands to be free of moving components.

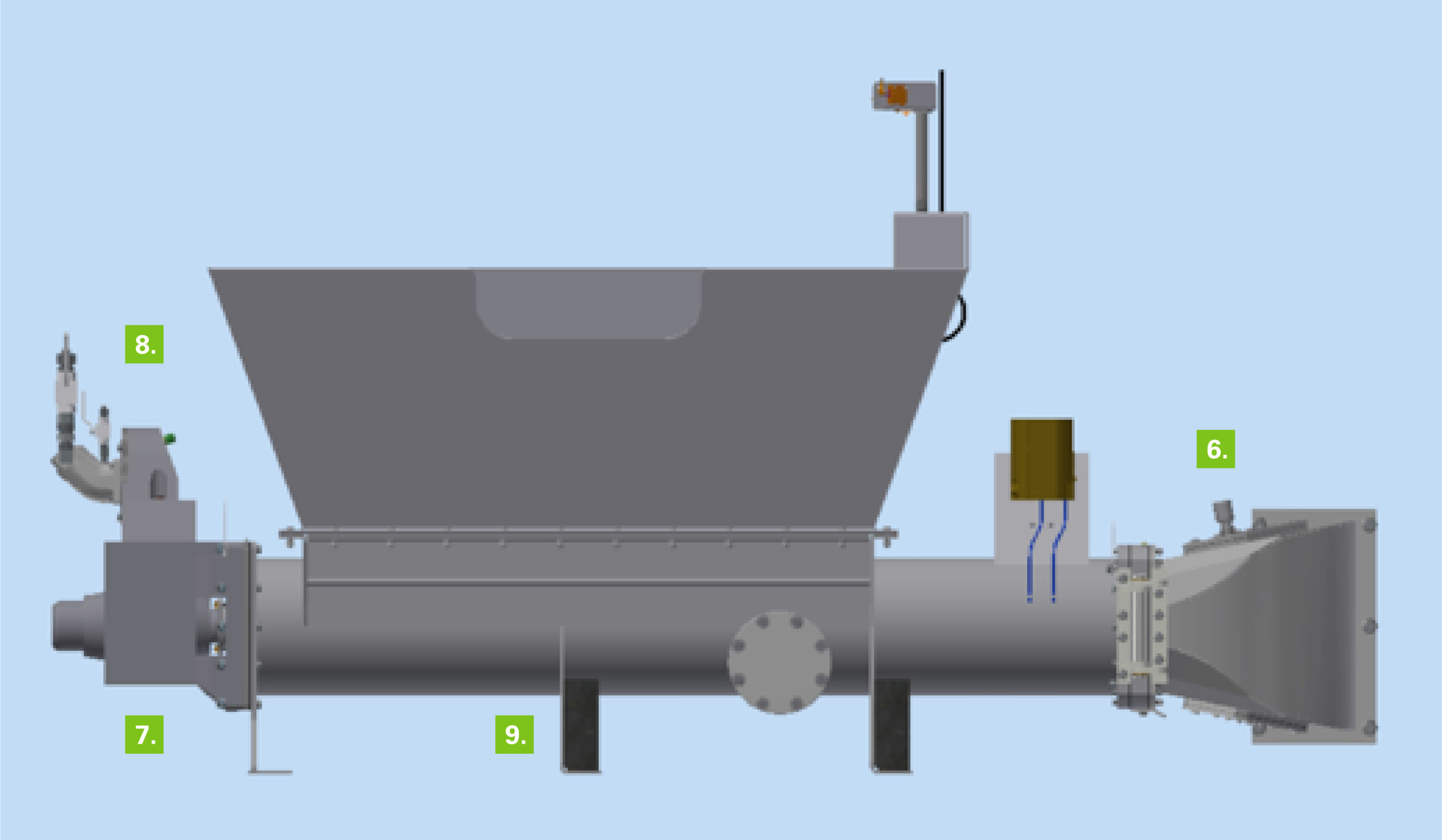

SCREWFEEDER

6. Transition Press Sensor controls the speed of screw feeder augers to ensure the pump attains its maximum filling efficiency while reducing power consumption and extending wear part life.

7. Screw feeder augers are driven by a timed gearbox that allows the flights to intermesh. This allows the screws to automatically clean themselves if sticky material begins to accumulate on the shafts or flights.

8. Screw Feeders can be driven either hydraulically or electrically.

9. Seven possible orientations of the screw feeder and piston pump are possible allowing the utmost layout flexibility

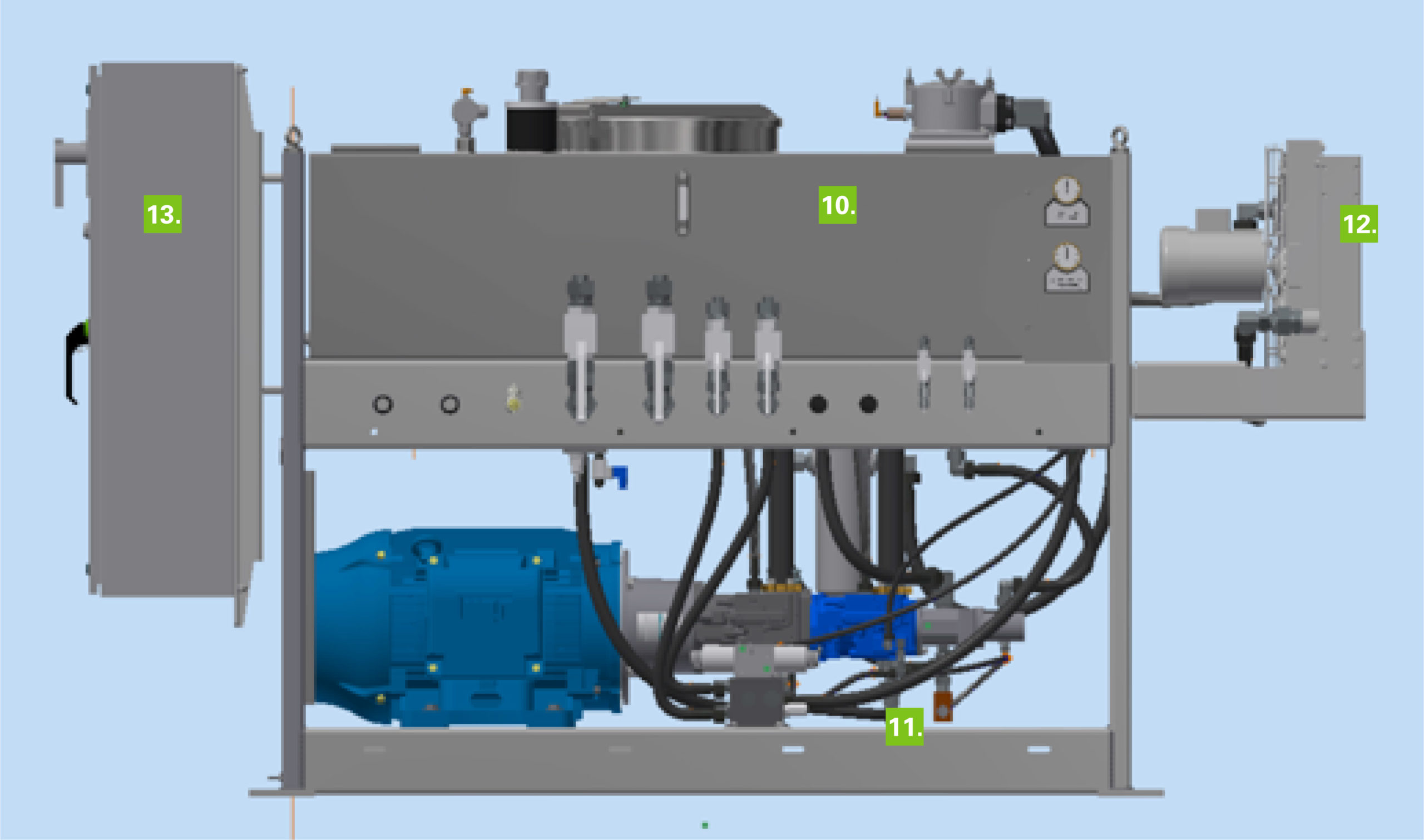

HYDRAULIC POWER PACKS

10. Open Loop hydraulic allows all oil to return to tank to be filtered.

11. No VFDs are required. Variable displacement hydraulic pumps control equipment speed.

12. Electronic Power Control (EPC) – If off-spec material causes an unexpected increase in pressure the EPC will automatically re-allocate horsepower to allow for higher operating pressures (still within delivery system limitations) and clear the pipeline to avoid costly shutdowns and pipeline clean-outs.

13. Twin motors provided for redundancy so in the event of a mechanical failure the system can continue to operate at reduced capacity and full pressure.

Project Gallery

Additional Resources

Piston Pumps & Screw Feeders Brochure

Read More

Screening Pumps Brochure

Read More

Smartec Sludge Pumps Brochure

Read More

Application Report #2

Read More

Application Report #4

Read More

Application Report #7

Read More

Application Report #9

Read More

Application Report #10

Read More

Application Report #11

Read More

Application Report #13

Read More

Application Report #15

Read More

Application Report #16

Read More

Application Report #19

Read More