Written by Kevin Bauer

The Concordia, KS, WWTF has produced liquid Class B sludge via aerobic digestion for land application since it was built. The facility was faced with the compounding issue of stricter EPA land application regulations and a reduced demand for Class B sludge from local landowners. In Kansas, Class B sludge can only be applied to agricultural fields not being used for human consumption. This requirement restricted the biosolids land application program to fodder crop fields that significantly reduced demand for the biosolids. As a result, the City had been forced to haul their Class B biosolids to a landfill 35 miles away. Liquid land application is further limited by the weather and can only be applied during the warmer months when there is no frost in the ground to prevent run off. The increased hauling cost resulting from the reduced demand for Class B sludge meant the city needed a new solution for their solids handling.

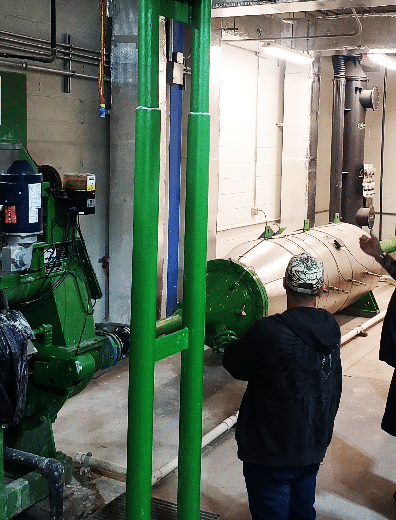

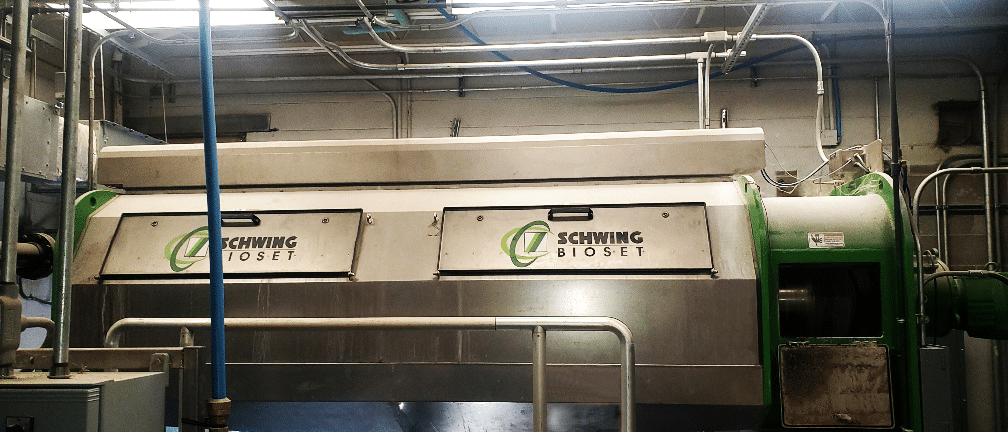

Several technologies, including composting, thermal drying, and lime stabilization were evaluated. Ultimately, the city decided to implement the Bioset Process, Schwing Bioset’s advanced alkaline stabilization process. This, in conjunction with a Schwing Bioset dewatering screw press to update dewatering operations, was the best solution not only for project economics, but for ease of use, maintenance, and odor control. The system was able to fit within the plants design constraints while producing a sludge quality that exceeded the existing process.

Several technologies, including composting, thermal drying, and lime stabilization were evaluated. Ultimately, the city decided to implement the Bioset Process, Schwing Bioset’s advanced alkaline stabilization process. This, in conjunction with a Schwing Bioset dewatering screw press to update dewatering operations, was the best solution not only for project economics, but for ease of use, maintenance, and odor control. The system was able to fit within the plants design constraints while producing a sludge quality that exceeded the existing process.

With the new system, the screw press dewaters the waste activated sludge to 22% dry solids, which is then fed into the Bioset Process, where it is blended with quicklime and sulfamic acid and pumped into the insulated plug flow reactor. The quicklime elevates the pH, releasing ammonia and creating an exothermic reaction that elevates the temperature. The released ammonia stays in contact with the biosolids within the flooded and pressurized reactor, and it, along with the elevated temperature, act as the stressors to kill pathogens and achieve USEPA Class A status. This nutrient-rich Class A soil is produced at the end of the continuous flow reactor after a residence time of only 40 minutes.

Since bringing the process online, Concordia no longer needs to haul Class B sludge to the land fill and the city has significantly reduced hauling costs. The Class A biosolids are land applied locally all twelve months of the year and are not restricted to specific fields. While the Bioset Process is widely used in other states, Concordia became the first wastewater treatment facility with this technology in the state of Kansas. Additionally, since Concordia is now able to produce Class A biosolids directly from their WAS sludge, they have started to transition away from their digesters. This provides further cost savings and reduces the plant’s operating costs, as the large electrical demand to operate the blowers is phased out. This has been a successful project for Concordia by any measure, which will serve their wastewater treatment plant, and the local agricultural community, well for many years to come.

Since bringing the process online, Concordia no longer needs to haul Class B sludge to the land fill and the city has significantly reduced hauling costs. The Class A biosolids are land applied locally all twelve months of the year and are not restricted to specific fields. While the Bioset Process is widely used in other states, Concordia became the first wastewater treatment facility with this technology in the state of Kansas. Additionally, since Concordia is now able to produce Class A biosolids directly from their WAS sludge, they have started to transition away from their digesters. This provides further cost savings and reduces the plant’s operating costs, as the large electrical demand to operate the blowers is phased out. This has been a successful project for Concordia by any measure, which will serve their wastewater treatment plant, and the local agricultural community, well for many years to come.

Contact us today to learn how Schwing Bioset can help your operation, or explore our website to read more about our products and solutions.

Download Our Brochures and Application Reports Subscribe to Start Receiving Schwing Bioset eNews