Escrito por Josh DiValentino

Fondo: The City of Spanish Fork, UT, Water Reclamation Facility (WRF) operates at 4 MGD capacity, with the current upgrade planning to double flow to 8 MGD by 2025. Today, the facility sends Waste Activated Sludge (WAS) to the dewatering building at 1% feed solids, typically running 40 hours/week. When complete, the 2025 upgrade will see the WRF’s treatment process change to a modern MBR system, improving flow and treatment standards. The dewatering portion of this project is needed to maintain reliability and performance throughout the multiphase upgrade that will span several years.

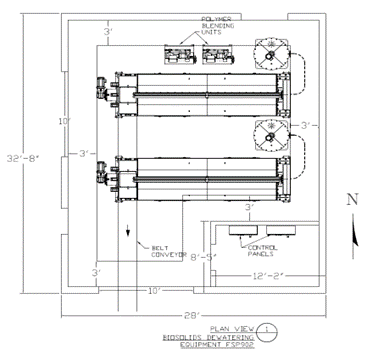

Figure 1 – Two (2) Schwing FSP902 Screw Press Retrofit Layout

Phase 1 & Phase 2 (2021): The Spanish Fork WRF and their consultant, JUB Engineering, issued an evaluated RFP to investigate various Screw Press dewatering systems. The selected system needed to provide dewatering capacity for up to 11,500 dry lbs./day and produce at least 16% dry cake solids and 95% capture. Critically important for phases 1 & 2 was to meet the design conditions, while also being able to functionally fit within the existing dewatering building that housed the outgoing Belt Filter Presses.

The Schwing Bioset FSP902 Screw Presses were the only units capable of meeting the flow requirements for the current and future flows, while also fitting well within the existing layout, due largely to the advanced features of the system, which include:

- High Performance Screens: Schwing Bioset screw presses offer industry leading pore density for the most open area per square foot of screen. This translates to higher solids throughput through smaller machines, which enables the Schwing Bioset press to process the plant loads and utilize the existing infrastructure. Other manufacturers required larger machines with greater overall footprints that simply would not fit in the available space.

- Uninterrupted Operations: The FSP series press offered by Schwing Bioset maintains dewatering operations while running its wash cycle, so operating time is not lost throughout the day.

- Sealing Lip: The elastomer lip on the screw flight wipes/cleans the inside of the screens during operation, improving machine capacity by preventing screen pores from blockage, unlike machines that do not include wipers. Simultaneously, the sealing lip allows the screw presses to maintain higher positive pressure on the sludge by sealing the pressurized zone and not providing a gap between the screw flight and screen ID. This is particularly important for treatment processes such as WAS and MBR that break down the biosolids prior to dewatering. Additionally, the wiper seal provides a wearing surface and is an easier item to maintain than rebuilding screw flights without wipers that will result in worn flighting.

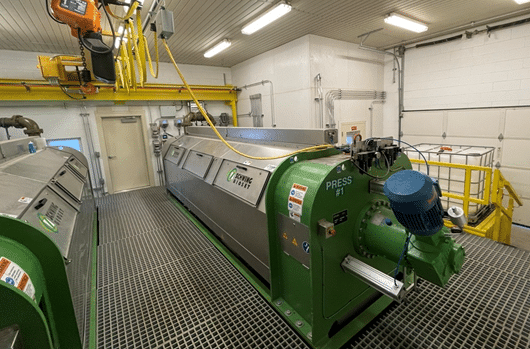

Figure 2 – Schwing FSP902 Machine in the Preexisting Spanish Fork Dewatering Building

The Schwing Bioset Screw Presses are now providing reliable dewatering for the entire Spanish Fork WRF while the full upgrade is being completed. The FSP series screw press dewatering systems offer this level of high-performance dewatering from a simple, easy to maintain, and low energy consuming package, meeting the full flow requirements at each phase of the upgrade WITHOUT the City needing to build an entirely new dewatering building.

Please watch for Part 2 of this story, which will include the dewatering performance details of the system once the MBR upgrade is completed and online in 2025. Part Two: High Volume MBR Dewatering at Spanish Fork WRF

Contáctenos today to learn how Schwing Bioset can help your operation or explore our website to read more about our products and solutions.

Descargue nuestros folletos e informes de aplicaciones Subscribe to Start Receiving Schwing Bioset eNews