Grit Hoppers, Trolley System, and Belt Conveyors for SFPUC

Written by Josh DiValentino, MS, MBA

San Francisco Public Utilities Commission (SFPUC) is in the final commissioning stages of a major headworks improvement at their 250 million gallons per day (MGD) wastewater treatment facility. The much-needed upgrade will increase capacity while adding several system improvements. Three custom Schwing Bioset systems provide vital transfer and storage for the management of grit and screenings waste:

System 1: Headworks Grit Storage Hoppers

SFPUC’s first SBI solution is two massive grit storage hoppers. Offering 72 cubic yards of storage each, the facility’s grit capacity worries are a thing of the past. Size doesn’t negate speed and efficiency, though. Each 316 Stainless Steel-fabricated hopper features load cells for easy inventory management, and custom 48” x 72” hydraulically actuated gates provide operational simplicity and peace of mind, all while loading trucks in 15 minutes or less.

Custom Fabricated 48” x 72” hydraulically actuated gates meter flow from each hopper.

The SFPUC was ready to “hop” into action the second each system arrived fully assembled bins ready for installation, no field welding required, saving valuable time and labor.

System 2: Screenings Trolley Hopper System

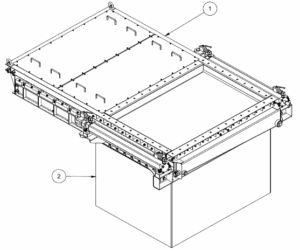

Facing tight spatial constraints and unique challenges, SBI created two fully automated 5-cubic-yard screening trolley hoppers, optimizing inventory management in a big way while maintaining a small footprint.

Each trolley drive system (shown above) is programmed to report to designated fill points under the washer/compactor discharges, receiving screenings material from the sluice gates. Level sensors reporting a full condition automatically move the trolley into the proper dumping position. The 48” x 48” electrically actuated gates open to the trailer below. Once complete, the system returns to the fill or parking locations as directed.

System 3: Screening Belt Conveyor

The last in SFPUC’s triad of SBI systems goes the distance with a screening belt conveyor. Two multi-rake screens feed the conveyor, which carries them across an 83’ horizontal run, up a 6’ incline before discharging into a compactor.

The belt system features fully enclosed stainless steel covers to mitigate odors, maintain a clean site, and protect the screenings from getting wet during inclement weather. Strategically placed access doors allow for operator viewing of the belt. While hinged covers offer unrestricted access to the entire belt for any maintenance, cleaning, or adjustments.