Los cambios recientes han preparado a la PTAR Bird Island del área de Buffalo para convertirse en una solución regional para la eliminación de lodos.

Escrito por Larry Trojak, Trojak Communications

Version also published in WE&T Magazine, July 2015

Compartiendo la riqueza

Las plantas de tratamiento de aguas residuales, como la mayoría de sus contrapartes comerciales en la actualidad, se ven obligadas a hacer frente a una serie de desafíos que incluyen el aumento de los costos, una base de clientes a menudo exigente y un panorama económico en constante cambio. Para abordar de manera eficaz estos y otros problemas, un número creciente de plantas está pensando de manera innovadora para mejorar sus operaciones. Para Buffalo (NY) Sewer Authority (BSA), ese esfuerzo creativo ahora incluye complementar su propio volumen de lodo deshidratado con un producto similar (pero más rico) de las comunidades vecinas. Hacerlo les permite reducir drásticamente los costos de combustible relacionados con la incineración y, al mismo tiempo, ayudar a esas comunidades con sus problemas de eliminación de lodos. ¿Compartiendo biosólidos? Parece que solo corresponde a una empresa de servicios públicos que presta servicios a la "Ciudad de los buenos vecinos".

Buen día en Black Rock

Fletada por primera vez en 1937 como una planta de tratamiento primaria, la instalación ahora conocida como la PTAR Bird Island cerca del distrito Black Rock de Buffalo se expandió para incluir un tratamiento secundario a fines de la década de 1970. Según Tom Caulfield, administrador de mejoras de capital y desarrollo de BSA, la expansión fue en respuesta directa a los mandatos de la Ley de Agua Limpia.

“That massive expansion — essentially, construction of a totally new secondary treatment facility — added aeration and secondary clarification capabilities,” he says. “Even today, few people realize that Bird Island is the second largest wastewater treatment plant in all of New York state. Only the Newtown Creek WWTP in Brooklyn’s Greenpoint community is larger. We are designed to handle a peak flow of up to 540 million gallons per day (MGD) but are currently averaging flows of about 130 mgd.”

In addition to the city of Buffalo, Bird Island WWTP serves a good number of other neighboring communities including the villages of Sloan and Depew, and the towns of West Seneca, Orchard Park, Alden, Lancaster, Cheektowaga, Elma and includes a limited amount of flow from the Town of Tonawanda. Despite that vast coverage, it was actually the nearby Town of Amherst which, by choosing to re-think its overall approach to sludge disposal, dramatically changed the complexion of Bird Island WWTP’s biosolids processing operation.

Plan B para Amherst

Durante más de una década, la ciudad de Amherst había estado deshidratando sus lodos, peletizándolos y trabajando arduamente para generar un mercado para ellos como un producto fertilizante de alta calidad. Sin embargo, en 2010, el aumento de los costos operativos, junto con el envejecimiento de los equipos, los llevó a repensar esa estrategia, según Michael Letina, superintendente de la planta de tratamiento de BSA.

“Amherst esperaba tener el mismo nivel de éxito con su granulado de fertilizante que el Distrito Metropolitano de Alcantarillado de Milwaukee ha tenido con su Milorganite, pero eso nunca sucedió”, dice. “Luego llegaron a un punto en el que sus digestores necesitaban reparaciones serias y, en lugar de incurrir en los costos de actualizar el sistema, comenzaron a buscar alternativas. Determinaron que enviar aquí sus lodos activados residuales [deshidratados] (WAS) tendría más sentido para ellos tanto desde el punto de vista logístico como financiero ".

A principios de 2010 se firmó un acuerdo de 10 años, aprobando el envío de material de Amherst desde sus instalaciones a Bird Island. Hoy en día, diariamente se transportan en camión alrededor de 70,000 libras de WAS desde Amherst hasta la ubicación de Black Rock.

Quemar o no quemar

Llevar a Bird Island a un punto en el que pudieran aceptar eficientemente el lodo de Amherst no fue una tarea fácil. Trabajando a través de la sucursal de Buffalo de la firma de ingeniería Arcadis US, Inc., se redactaron y consideraron planes, y el contrato de construcción final de $2.38 millones ofreció un par de opciones para el material que se entregaba.

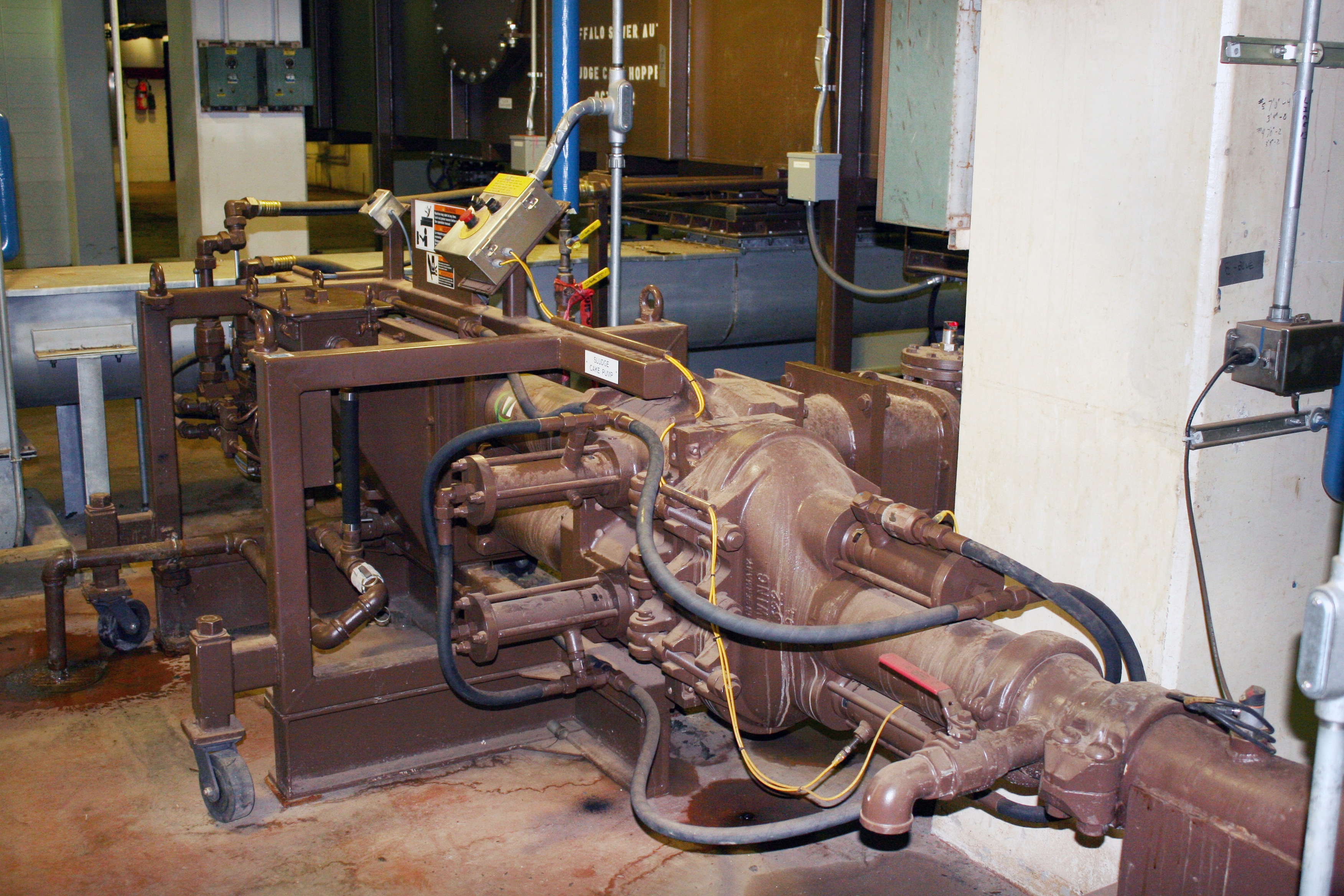

“Essentially, the process began with construction crews cutting a hole in the15-inch thick floor of our truck weighing area, and installing a 60 cubic yard push floor bin supplied by Schwing Bioset (Somerset, WI). There, customers’ vehicles — at the beginning it was only the Town of Amherst’s trucks — could empty the dewatered WAS they were delivering,” says Letina. “The hopper contains a hydraulic push-floor that sends material through a gate where it drops into a screw feeder, then into a Schwing Bioset KSP 12V (HD) pump designed for 1,000 psi operating pressure which pushes it up to the third floor for incineration. Depending on our needs at the time, we also have the option to take that sludge out of the bin through an alternate extraction screw conveyor and drop it down to the sub basement where it can be re-wetted and sent to our digesters to produce methane.”

Adding Amherst’s dewatered WAS to the operation was a win-win in a number of regards. Not only did it address the town’s needs to effectively dispose of its sludge, the material’s high volatile content — generally in the 76% range — proved an excellent fuel for Bird Island’s incineration effort.

“Nuestros propios biosólidos se digieren anaeróbicamente y, como resultado, son solo un 46 por ciento volátiles, por lo que se necesita una cantidad considerable de gas para quemarlos”, dice Letina. “Sin embargo, poner material de Amherst encima es como arrojar líquido para encendedor a una llama abierta. Ahora, monitoreamos continuamente para ver si la producción de metano o la incineración nos servirán mejor. Es un buen lujo tenerlo ".

En el Up and Up

With the Amherst-generated cake added to the equation, steady, reliable equipment operation is key to ensuring that both plants realize the maximum benefit of the new effort. The Schwing Bioset biosolids pump installed as part of the recent expansion has definitely risen to the challenge, says Alex Emmerson, BSA’s process coordinator.

“The pump has its work cut out for it, taking material that is generally in the 26% to 28% solids range and sending it more than 65 feet straight up to the conveyor feeding the incinerator,” he says. “To handle issues of excessive in-line friction, Schwing Bioset also supplied an injection-ring system that lubricates the pipe wall with a small amount of fluid as it moves.”

On average, Bird Island maintains about 900,000 pounds of inventory on its secondary treatment system. They recently had a case, however, in which inventories ran low, prompting the need to curtail wasting. “That meant we had to rely solely on the ‘outside’ Biosolids and really push the pump — sometimes operating it at three times its normal speed,” says Emmerson. “Even with the added workload we were consistently pumping 8,000 pounds per hour and never had an issue. It’s definitely a key part of the operation.”

Agrega que hay una cierta tranquilidad al saber que la operación de biosólidos externos (que recientemente se expandió para incluir un acuerdo similar con la ciudad de Tonawanda) les brinda un buen plan de contingencia.

“Now we know we are covered if something unforeseen — like a centrifuge failure — occurs and we need to step up production using the imported biosolids to meet incinerator demand.”

Dinero en el banco

BSA has been prepping for growth for some time now, an effort that included a recent incinerator rehab. According to Letina, that updating, which included a new scrubber pack and burners, and carried a price tag of nearly $5 million, allows them to meet new environmental regulations that take effect in March, 2016. However, their ability to become a regional biosolids processor — and keep costs steady in doing so — is a real source of pride.

“Much of the preliminary work for this part of the operation is the brainchild of Jim Keller our treatment plant superintendent and Roberta ‘Robbie’ Gaiek, BSA’s plant administrator,” says Caulfield. “Because of their planning and foresight, we are already seeing the fruits of this effort. Before the installation of the centrifuges and digesters, this plant used about 550,000 decatherms (Dth) of natural gas a year; now we are averaging about 175,000. So we’ve effectively cut our gas consumption by about 65%. With the rehabbed incinerator and addition of the higher volatile material from Amherst and Tonawanda, even with the added volumes we hope to be down around 150,000 to 160,000 Dth a year.”

The savings realized from Bird Island’s reduction in fuel costs is being reinvested in onsite projects, eliminating the need for bonding and the headaches that come with it. “More importantly,” says Caulfield, “it has also allowed us to go nine years now without a rate hike to our customers. In light of what the economy has been through, not a lot of utilities can say that.”

Viendo hacia adelante

Los planes futuros que se están considerando —con ahorros adicionales anticipados— incluyen un proyecto de calefacción y energía diseñado para recuperar y reutilizar los gases de escape de los incineradores de la planta.

“The original plan was designed to incorporate the use of three waste/heat recovery boilers, says Letina. “Once operational, the exhaust off the afterburners would create steam which would power a turbine and generate 1.5 – 2 megawatts of electricity — about 1/3 of our current load. Our electric bill right now is substantial — about $4.5 – $5 million a year. If we can save another $1.5 to $2 million annually, that money can be reinvested into the infrastructure, again avoiding bonding and rate hikes. The last few years have been challenging but definitely worth the effort. With these proposed changes and our growing role as a regional biosolids processor, this is an exciting time for Bird Island and BSA overall.”

Para obtener más información sobre Schwing Bioset, nuestros productos e ingeniería, o este proyecto específicamente, llame al 715-247-3433, envíe un correo electrónico marketing@schwingbioset.com, ver nuestro sitio web, o encuéntrenos en las redes sociales.

Para ver una versión de esta historia publicada en WE&T Magazine, haga clic aquí.

Descargue nuestros folletos e informes de aplicaciones

Subscribe to Start Receiving Schwing Bioset eNews