Escrito por Joe Scholl, 11 de febrero de 2016

The word “heat” may be defined as the amount of energy that is transferred from one system to another, typically via a temperature differential or “gradient,” and the amount of heat something possesses may be stated in terms of British Thermal Units (BTU), Joules (J), calories (cal), etc. (as compared to reference temperature or datum state). Measured over time, heat becomes energy that is used to accomplish tasks, and that energy may be measured in BTU/hr, J/sec, etc. There is a definite cost to energy usage, as evidenced by any plant’s energy utility bill. As such, there is a high emphasis nowadays in energy re-use (“heat integration”) via applying “waste” heat from one process to another process needing energy. While many such heat/energy integration techniques may be easily accomplished, there may, under certain circumstances, be limitations to the extent such energy re-utilization efforts may be accomplished.

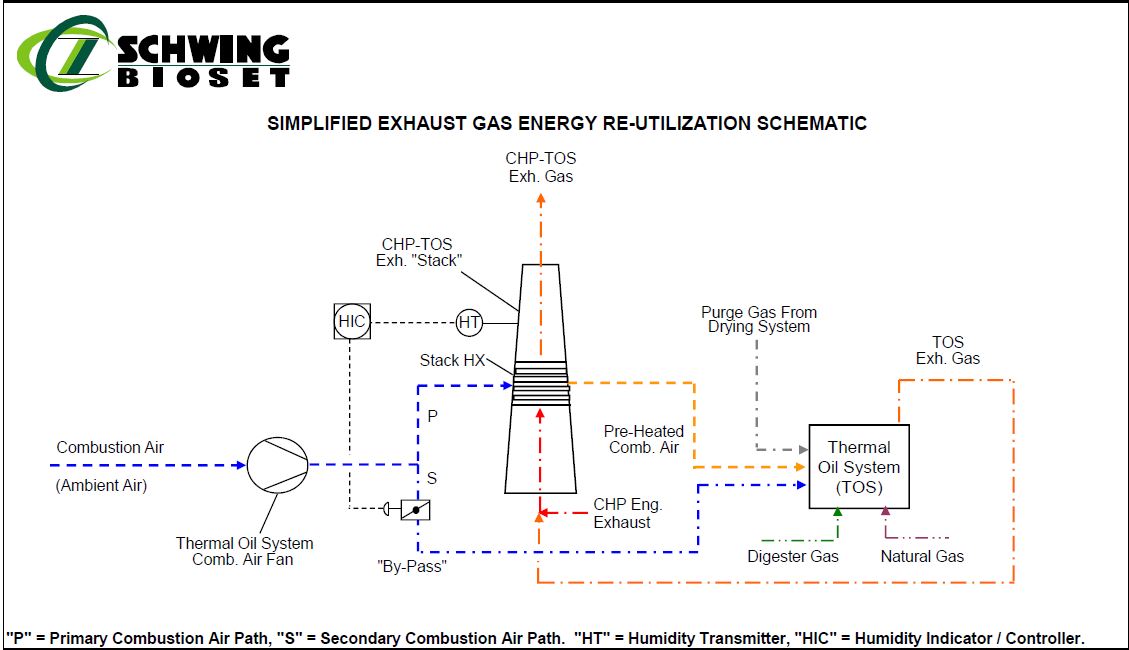

Many municipal wastewater treatment plants (WWTP’s) are utilizing anaerobic digestion systems and these processes may produce digester gas or “biogas” (chiefly methane and carbon dioxide with other trace chemical constituents and/or contaminants). The biogas produced may be used by a variety of means, such as for maintaining heated conditions in the digester units and/or in gas engines that drive generators to produce electricity in a combined heat and power cycle (CHP). These CHP processes generally produce two “waste” heat streams by which heat may be extracted and re-utilized (i.e. “integrated”) in another process. These two streams are the exhaust (or “stack”) gas from the biogas combustion process itself and a hot water stream (typically a water/glycol mixture) or steam produced from using cooling water to maintain reasonable CHP engine temperatures.

The extent to which these particular waste heat sources can be utilized depends on many factors, including the costs associated with purchasing, installing, and operating the heat recovery equipment. With respect to utilizing a waste heat source in a sludge thermal drying operation, some of these factors may include:

- ¿Qué tan cerca del sistema de secado está la fuente de calor? Específicamente, ¿cuáles son los costos de movimiento de fluidos desde el punto A al punto B, en términos de requisitos de bombeo de líquido o manejo de gas y cómo afecta esto a la estrategia general de integración de calor?

- ¿Cuál es el requisito de gasto de capital adicional ("Capex") para instalar tuberías o conductos aislados desde la fuente hasta el sistema de secado? ¿Son estos requisitos de Capex tan altos que la recuperación de la inversión para incorporar el calor residual en el sistema de secado resulta en una recuperación excesivamente larga? ¿período?

- ¿Son los problemas de corrosión a largo plazo una preocupación, como los materiales de selección para las tuberías de gas del digestor, conductos de gas de chimenea, etc. (especialmente si los "gases ácidos" se condensan fuera de la corriente de gas al enfriarse, lo que genera condiciones corrosivas dentro de la tubería, ductos o equipos de transferencia de calor) y, de ser así, ¿cuál es su impacto en el Capex, así como el impacto en los gastos operativos (“Opex”) (por ejemplo, los problemas de corrosión a largo plazo requerirán gastos de mantenimiento a largo plazo)?

- How much heat will the waste heat stream lose from point A to B and will this heat loss drive the heat recovery economics toward an unfavorable overall result? This point is particularly important if the waste heat stream is steam, where the latent (or condensing/phase change) heat of the steam is the primary (or desirable) heat transfer mechanism. For example, if the waste steam loses sufficient energy in transit from its source to the drying system, will the steam lose so much heat that it condenses to liquid form, thereby “robbing” the heat integration scheme of the steam’s latent/condensing heat prior to the drying system (noting that the latent/condensing heat of steam is significantly higher than the specific heat capacity of either the steam or liquid forms)?

In general, there are many possibilities for incorporating waste heat into a thermal drying process. However, the costs (in terms of Capex and Opex considerations) to incorporate the heat integration step must also be considered to determine whether doing so is practical.

Para obtener más información sobre las estrategias de integración del calor residual y nuestra tecnología de secado de lecho fluido, comuníquese con un gerente de ventas regional de Schwing Bioset llamando al 715-247-3433, Envíenos un correo electrónico, y / o visite nuestro sitio web aquí.

A continuación se muestra solo un ejemplo de las numerosas posibilidades de recuperación de calor.