Version also published in TPO Magazine, October 2022

When designing their new biosolids drying facility, the Des Plaines, IL, Water Reclamation Facility wanted to be able to process their own dewatered cake, as well as cake from external sources. With limited space and specific volume requirements, they needed a custom cake storage solution for their plant.

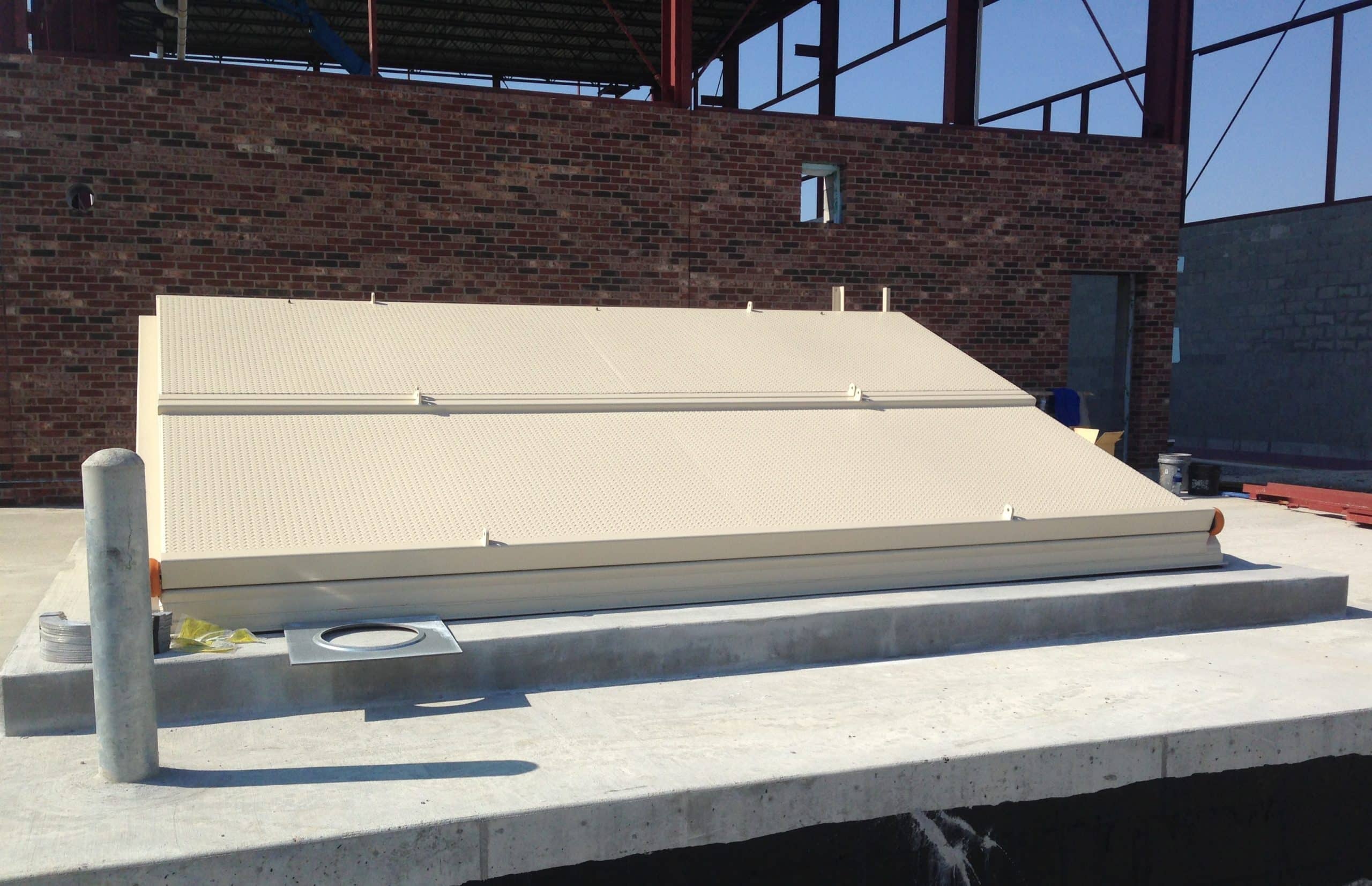

Schwing Bioset was able to work with Des Plaines to provide a custom solution to meet the challenges of receiving, moving, and storing dewatered biosolids for the dryer. Schwing Bioset manufactured a custom designed receiving bin with an innovative push floor design to receive the outside cake. The bin includes a safety screen to prevent large tramp material from entering and a bi-fold cover to contain odors.

The push floor feeds cake to the pumps with a hydraulically driven push floor. The main storage silo within the plant collects dewatered cake from the receiving bin, as well as dewatering, to feed to the dryer. The main storage silo utilizes sliding frame technology similar to the push floor but with a single frame constructed of carbon steel to feed cake to the discharge.

The Des Plaines WRF is able to continuously and smoothly operate their biosolids dryer with biosolids produced within the plant, as well as those received from outside the plant, thanks to the buffering storage provided by the Schwing Bioset receiving and storage bins without needing any additional operators or maintenance staff.

Visite nuestro sitio web to read more about our products and solutions, then Contáctenos para obtener más información sobre este proyecto o descubrir cómo podemos ayudar también a su planta.